Precision accuracy is the hallmark of our work. With all our fabrication processes housed under one roof, every single component is rigorously tested against our quality and specification metrics.

The integration of Industry 4.0 and development of our smart factory unites formidable digital technology with our team of highly skilled engineers.

Combined, these two elements provide increased efficiencies and outstanding quality control.

The result? Exceptional outcomes for our clients.

Because we have full in-house control of our fabrication processes and supply chain, we guarantee perfect precision in every component.

- CNC controlled for precision and accuracy

- Highly skilled engineers and technicians control the process

- Small or large batch production

- Ferrous and non-ferrous metal fabrication and machining

- CMM testing

- Quality assured – fully documented via our QMS and ERP systems

- ISO 9001 certified company

- Manufactured to Australian standards

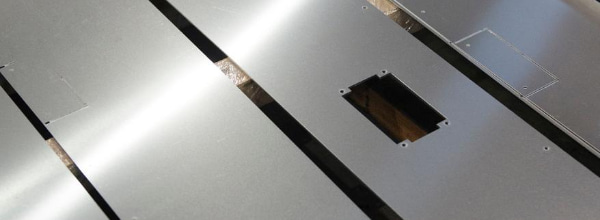

CUTTING

With unrivalled expertise and exceptional capability, we utilise state-of-the-art technology to offer CNC laser cutting services across all industry sectors.

FINISHING

Here at Sevaan Group, we know that quality finishing is vital to ensure your product meets industry standards and performs perfectly in accordance with your specifications.

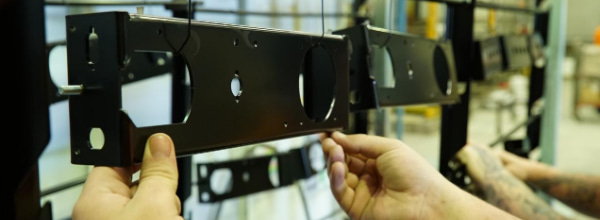

ASSEMBLY

Assembly completes our end to end metal engineering, fabrication and finishing solutions. It is the final critical stage of the process that must be performed quickly and efficiently.

02 9824 5555

02 9824 5555